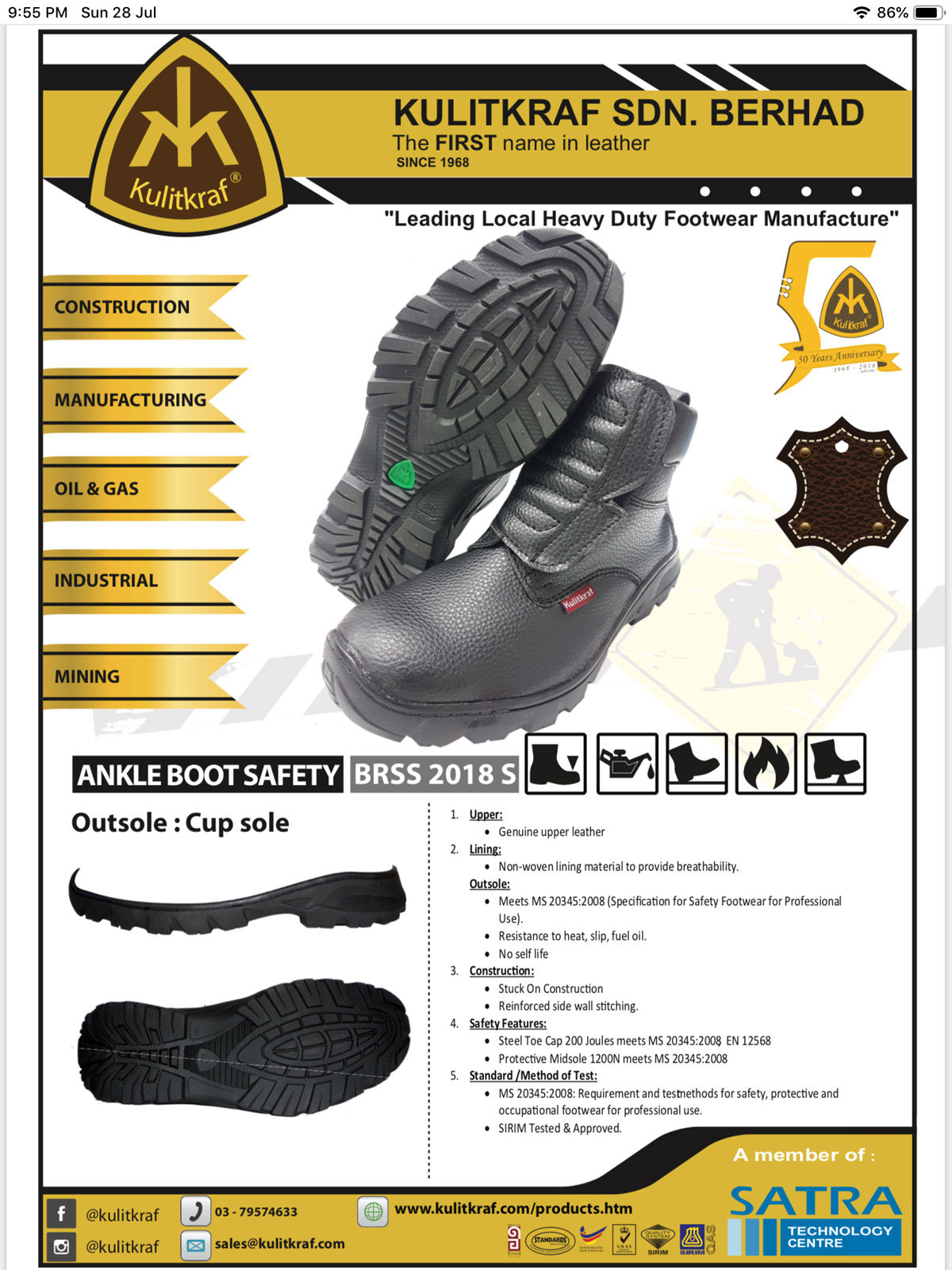

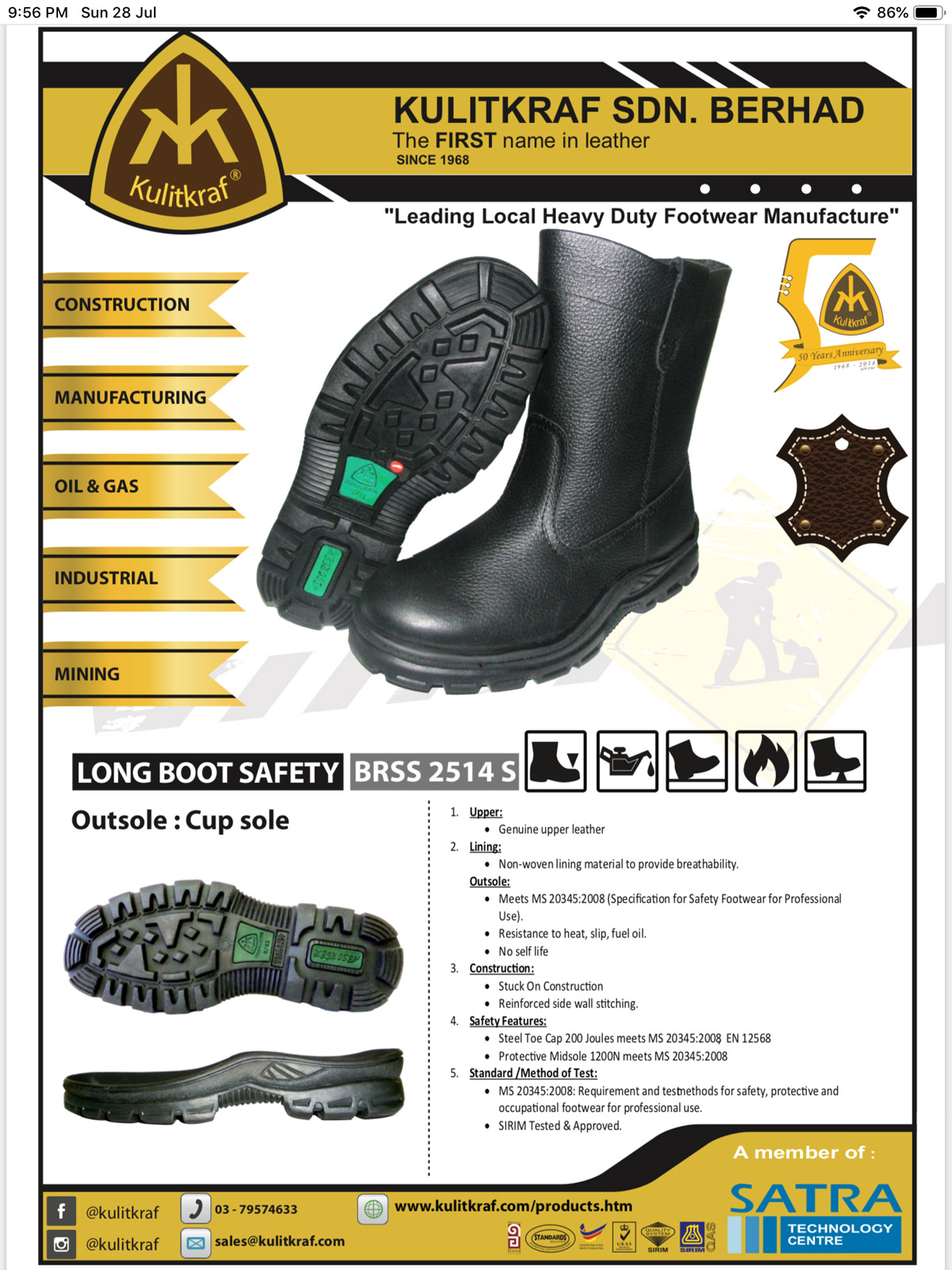

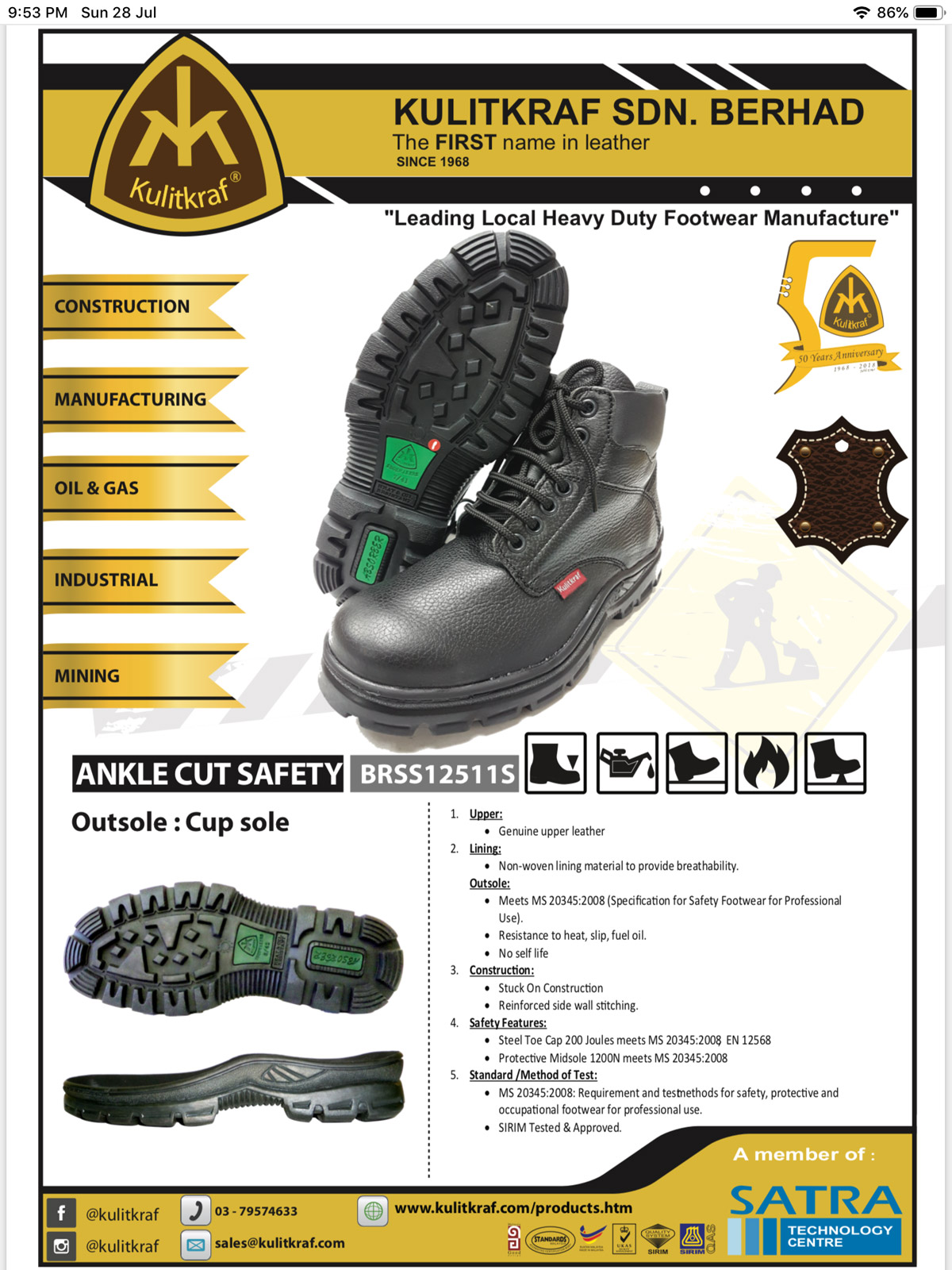

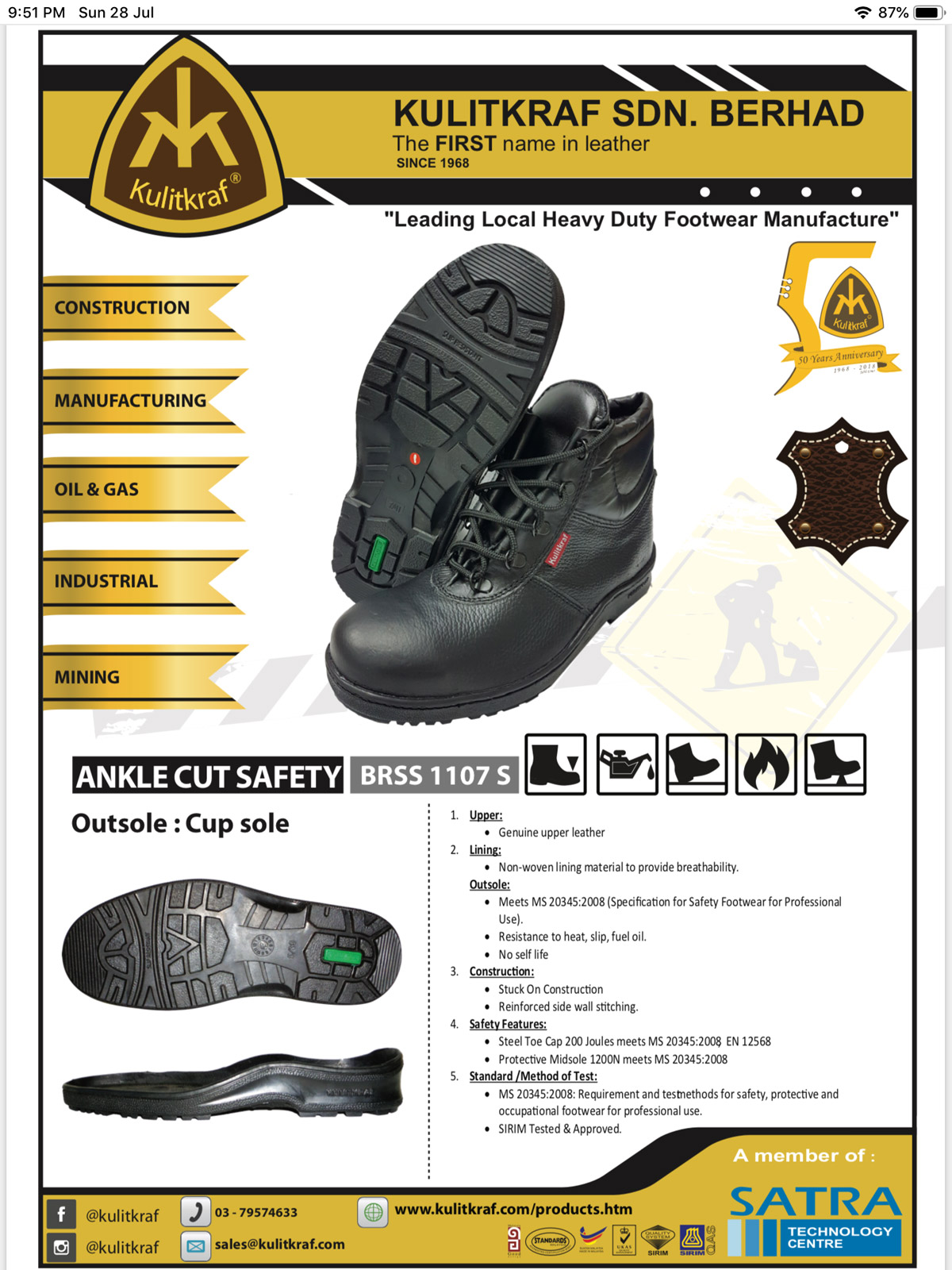

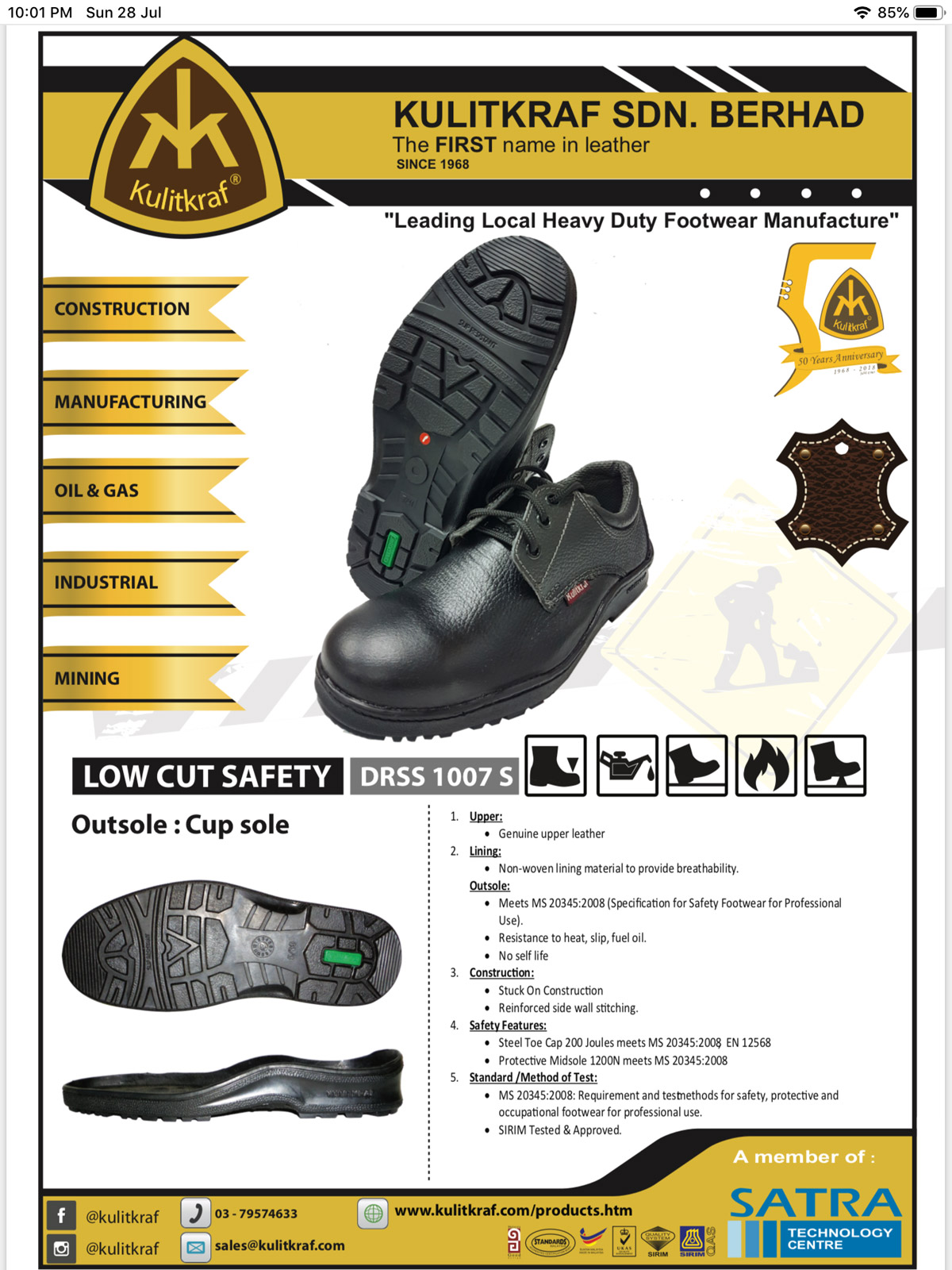

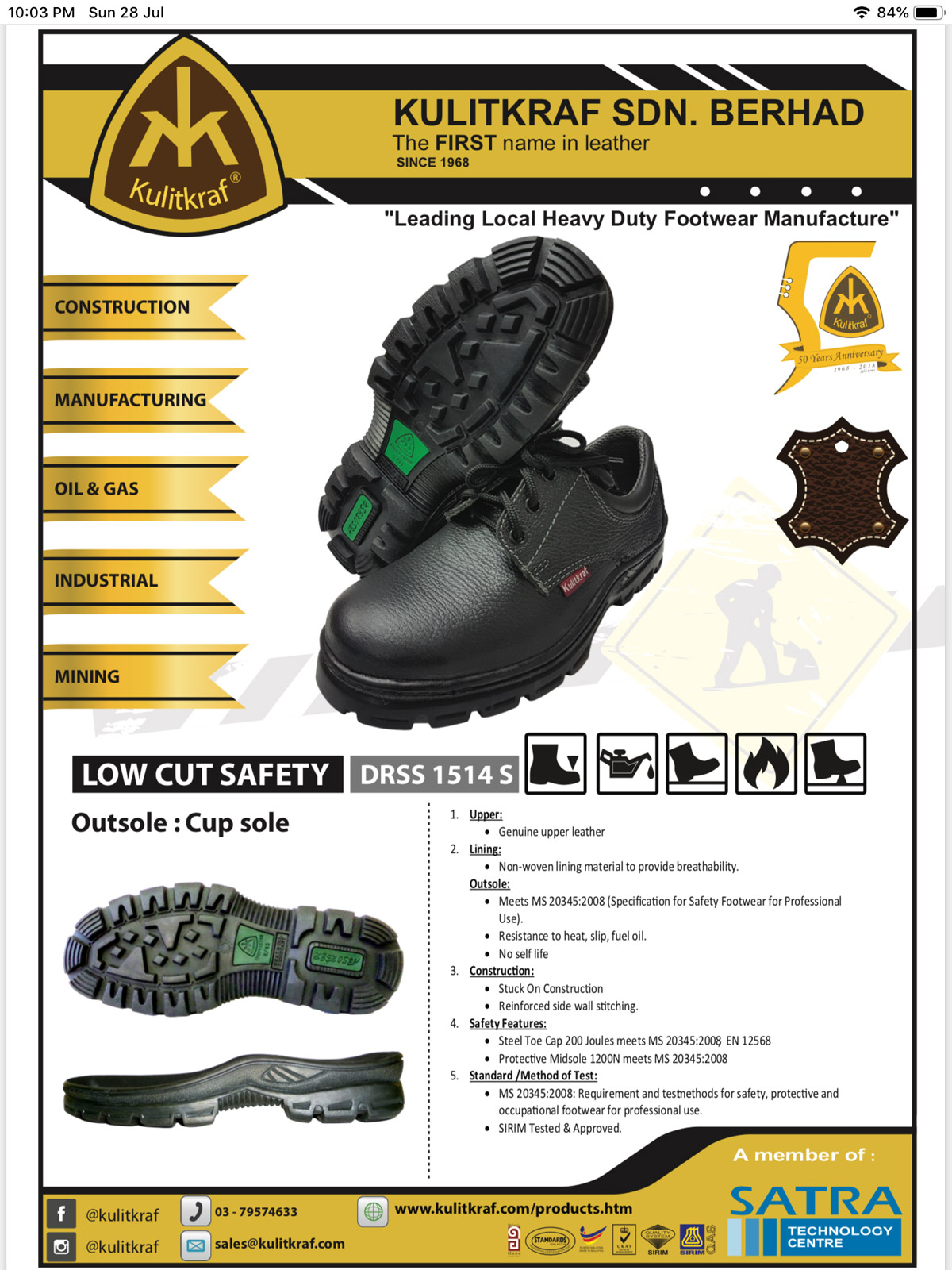

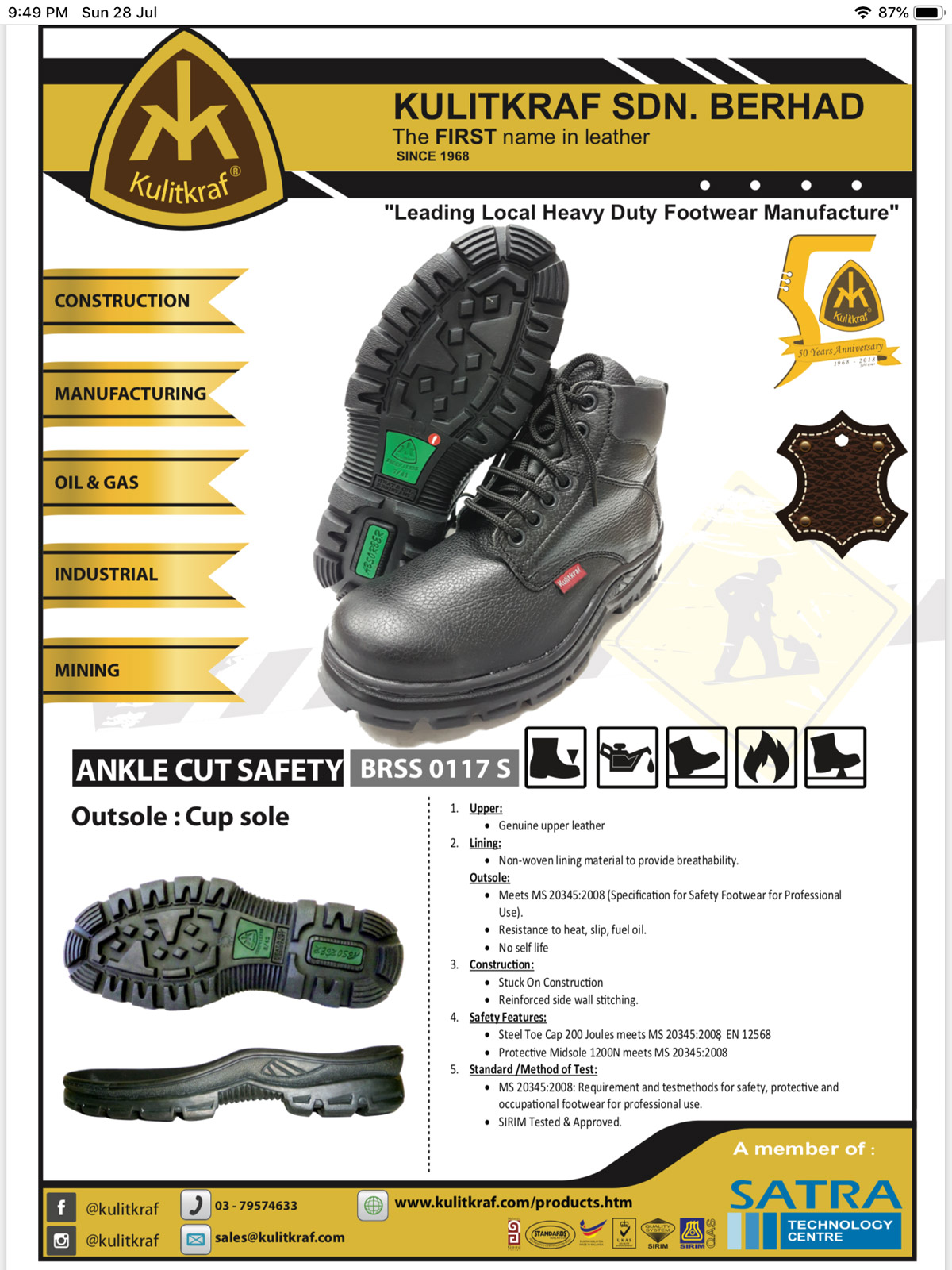

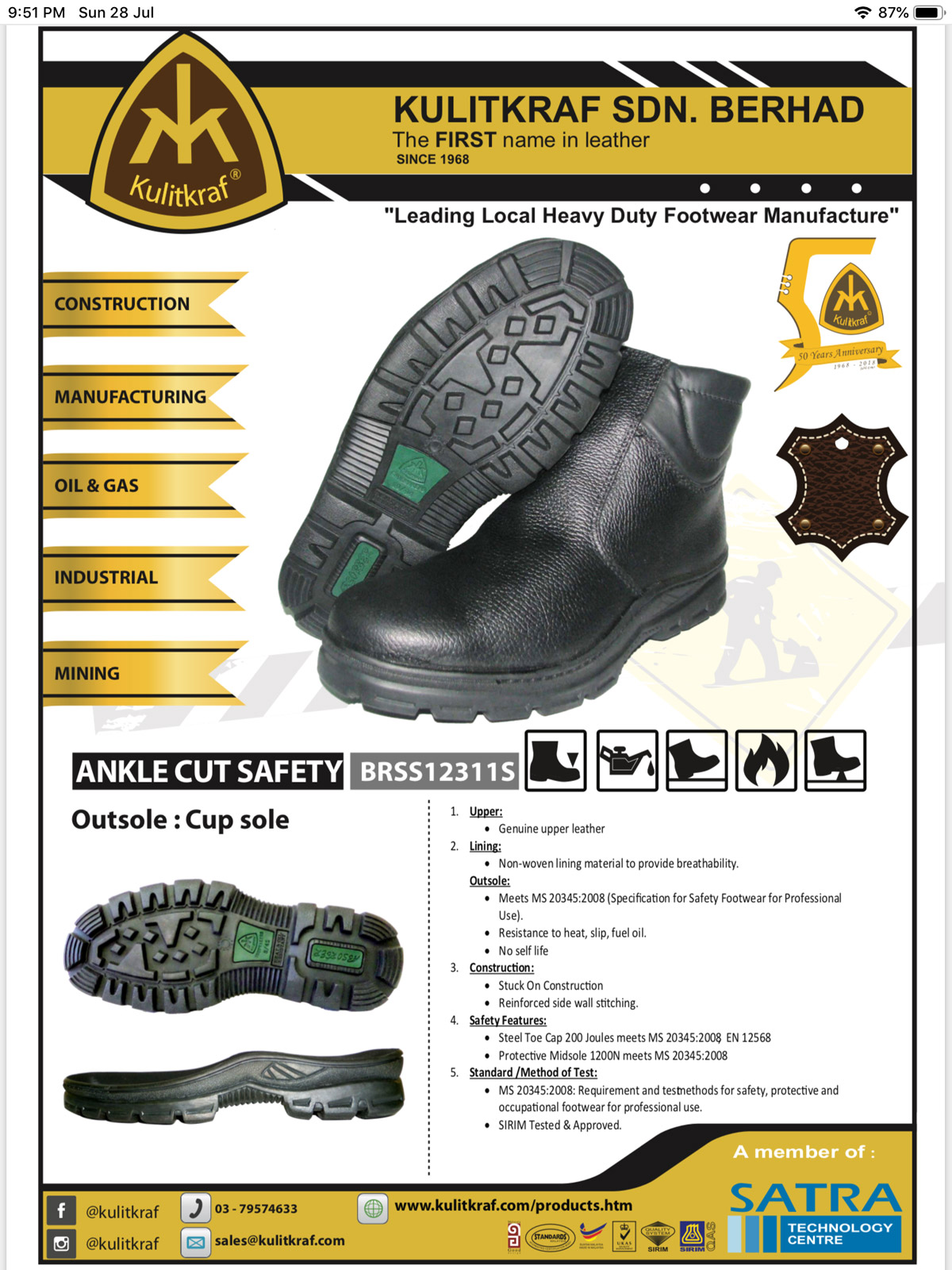

Product Photos and Details

Click photo for more info.

How It is Being Made

Goodyear Welted Construction

The standard in durable performance. Rib welt is first attached to the insole and then uppers are directly stitched to the rib and welt. The welt is then stitched to the insole that is directly attached to the outsole. There is no other better way to achieve the stability that keeps you sure footed and performance that never says quit.

Direct Moulded Construction

The soles are directly moulded to the lasted uppers. These boots are machine bonded. The sole material expands and forms an extremely strong bond directly to the bottom of the shoe for high sole performance.

Stuck-On Construction

Cemented models provide lightweight, flexible and comfort that is still tough enough to outwork any other boots on the job. The leather upper and the cup soles are roughened, cemented, and then fused to each other. This process creates a durable flexible boot that keeps feet comfortable day after day.

General Features

- Upper Leather - Chrome Tanned Full Grain Leather

- Cushion Insole

- Puncture Resistant Steel Midsole 1200N

- Heat/Oil/Slip Resistant (Sole)

- Steel Toe Cap 200 Joules

- Rubber Sole

- Non Woven/Canvas

Working Conditions

- Dry/Wet Environments

- Oil and Gas (Sole)

- Dry/Wet and Slippery Floors

- Hard Surface

- Sharp Stone and Metal Chips

- Terrain

- Construction Area

- Platform (Gas/Oil)